When Oil Prices Fall, Smart Energy Decisions Look Further Ahead

Release time: 2026-01-16

Table of Contents

Recent signs of global oil oversupply and downward pressure on fuel prices have sparked renewed debate among commercial and industrial energy users. For some, cheaper diesel appears to justify postponing solar and energy storage projects.

In practice, this approach underestimates long-term energy risk.

Fuel price dips are typically driven by short-term supply imbalances. They do not eliminate structural drivers such as carbon pricing, renewable mandates, electrification, or grid reliability challenges. For diesel-dependent sites — including industrial parks, mining operations, agricultural pumping stations, and remote facilities — temporary savings often mask future exposure.

Why many enterprises are acting now

From recent projects, three factors stand out:

Favorable procurement conditions

Global manufacturing capacity has improved equipment availability and pricing for high-quality solar and storage components, especially for customers planning multi-year assets.

Improved financing environments

More stable commodity markets allow clearer modeling of project cash flows. In many regions, green financing, supplier credit, and local energy loans further enhance feasibility.

Long-term cost predictability

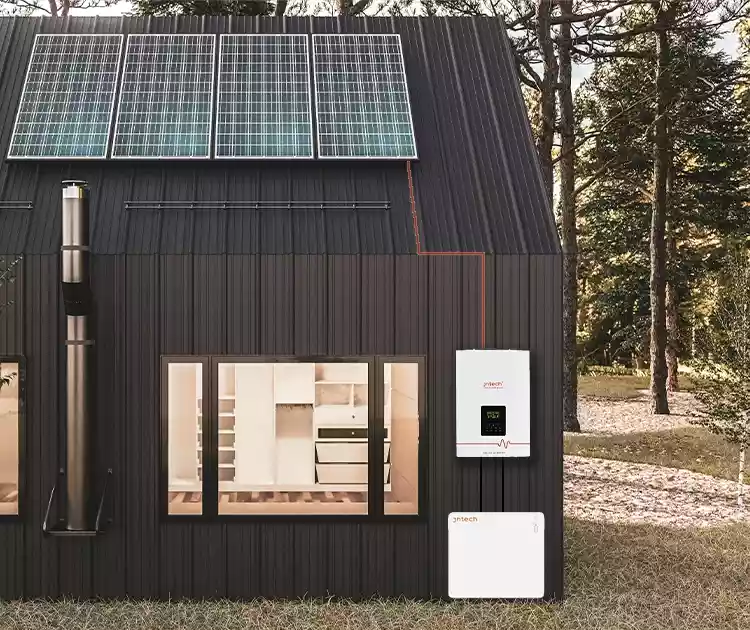

Solar-plus-storage systems convert volatile operating expenses into stable, partially prepaid energy assets, reducing dependence on fuel markets.

The hidden differentiator: technical service

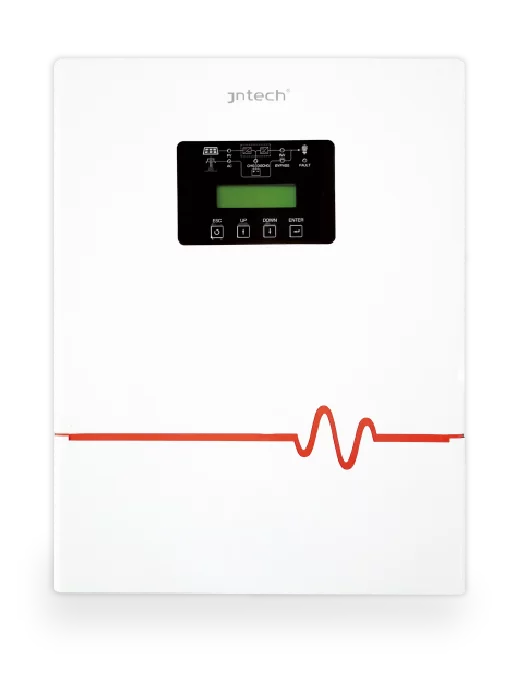

Field data and user feedback consistently show that system failures are rarely caused by core technology alone. Common issues include thermal stress on inverters, incorrect wiring, insufficient ventilation, and lack of preventive maintenance.

The wave of installer bankruptcies between 2024 and 2025 left many system owners without service support, creating the “solar orphan” problem — functional assets with no one responsible for their operation.

This has accelerated an industry-wide shift: from selling equipment to delivering end-to-end system reliability.

Advanced BMS platforms, AI-based predictive maintenance, standardized installation practices, and localized service teams are now essential to achieving acceptable ROI over a 10–15 year lifecycle.

Engineering for extreme environments

Standard solutions often fail in complex conditions. Projects such as high-head variable-frequency water supply systems in karst regions demonstrate the importance of integrated design, precise parameter matching, and on-site commissioning expertise.

Similar lessons have emerged globally — from hurricane-resilient systems in the Caribbean to virtual power plant deployments in the US and increasingly stringent safety standards such as UL9540A and NFPA 855.

Looking ahead

The competitive landscape in solar and energy storage is no longer defined by manufacturing scale alone. It is defined by the ability to deliver systems that perform reliably, year after year, under real-world conditions.

At JNTech, our focus remains clear: turning energy uncertainty into long-term, bankable value through engineering depth, global experience, and sustained technical support.

→ JNTech Technical Support in Saudi Arabia

→ JNTech Technical Support in Bangladesh

More info → www.jntechenergy.com

GET A QUOTE OR PARTNER WITH US

Contact our team for pricing, bulk orders, or business opportunities.