From Bidding to Operation and Maintenance: Common Failure Cases and Replicable Preventive Measures in Microgrid Projects

Release time: 2026-01-30

Contents

The success of a microgrid project depends not only on hardware procurement but also on technical services and system integration throughout its entire lifecycle. This article deeply analyzes typical failure cases of microgrids from the bidding and construction phases to the operation and maintenance (O&M) phase, revealing how to shift the focus from low-price competition to long-term system availability through systematic preventive measures, rigorous O&M SLAs, and data monitoring platforms, ensuring a sustained return on energy investment.

Avoiding the Long-Term Trap of “Lowest Bid Wins”

In the microgrid field, “whose equipment is cheaper” is often the focus during bidding, but “who can guarantee the system won’t fail for ten years” is the key to profitability. A microgrid is not a simple aggregation of components, but a complex energy balance system. If the technical capability assessment during bidding and continuous support during the O&M phase are neglected, initial “cost savings” often evolve into later “asset write-offs.”

Systemic Reasons for Microgrid Failures

Most microgrid project failures stem from poor system interoperability, lack of sophisticated BMS/EMS data monitoring, and insufficient local spare parts supply. When project owners unilaterally pursue the lowest initial investment (CAPEX) while neglecting TCO estimation, including O&M expenses and performance losses, the system is predisposed to failure.

Analysis of Typical Failure Cases

1. Bidding Phase: “Zombie Power Plants” Caused by Mismatched Equipment Selection

- Key Failure Point: A remote community project in Morocco only considered unit price during bidding, without conducting a thorough load curve matching analysis.

- Consequences: After the equipment arrived, it was discovered that the inverters could not support the local peak inductive load, leading to frequent system tripping. Ultimately, the system remained idle for a long time due to the inability to provide normal power supply, resulting in asset depreciation.

- Preventive Measures:

- Increase the weight of “system design and load matching” in the bidding evaluation criteria.

- Require suppliers to provide detailed simulation operation reports. – Communication Script: “Please provide system availability reports and fault lists for the past 3 similar projects.”

2. Construction and Commissioning Phase: Communication Protocol Incompatibility “Islands”

- Failure Point: During construction, it was discovered that the communication protocols of the BMS (Battery Management System) and EMS (Energy Management System) were inconsistent, and the manufacturers were uncooperative.

- Consequences: The system could not achieve automatic logical scheduling, requiring manual intervention, leading to low operating efficiency and safety hazards.

- Preventive Measures:

- Clearly define system interoperability specifications in the procurement contract.

- Require strict Site Acceptance Testing (SAT).

- KPI Example: Data reporting completeness rate > 99.5% (example/to be localized).

3. Operation and Maintenance Phase: “Power Outage Crisis” due to Lack of Spare Parts and Technical Support

- Failure Point: In a microgrid in a mining area in Africa, after a critical module failed, the manufacturer had no local spare parts warehouse and no remote monitoring platform.

- Consequences: Logistics and expert arrival took two months, and the downtime losses far exceeded the initial savings on equipment price differences.

- Preventive Measures:

- Establish spare parts response time constraint clauses.

- Require a local operation and maintenance personnel training and certification program.

- KPI Example: Mean Time To Repair (MTTR) < 48 hours (example/to be localized).

From Product to System: Three Key Focus Areas of Technical Services

1. System Architecture Design and Interoperability

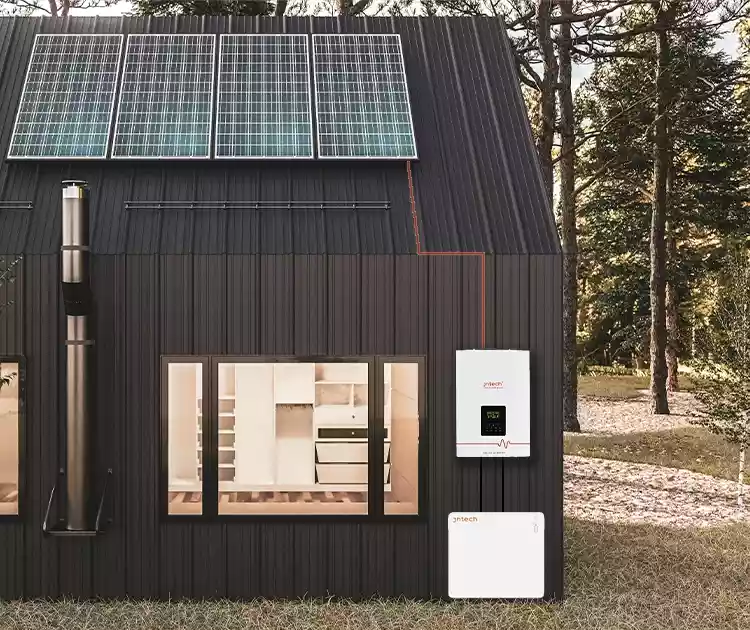

An excellent microgrid is not just about buying good inverters and batteries, but about buying a mature coordinated control logic. System interoperability determines the flexibility of future equipment replacement or expansion, avoiding being deeply tied to a single hardware vendor.

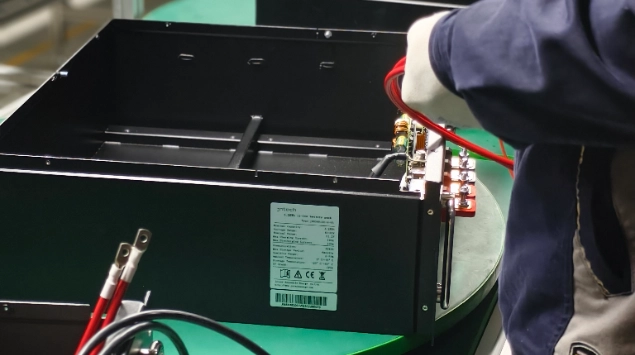

2. BMS/EMS and Data Capabilities

Data is the eyes of operation and maintenance. A powerful EMS can predict battery State of Health (SOH) in real time through a remote monitoring platform, providing warnings before failures occur.

- Key Indicator: System availability percentage should be a core annual acceptance target.

3. Operation and Maintenance Services and SLA Mechanism

Technical support should be “with a contract, with a response, and with spare parts.” Clearly defining response times in the O&M SLA (Service Level Agreement) is the only way to reduce hidden costs.

Procurement/Tender Checklist (Technical and Service Proposal Clauses)

- BMS Interface Specifications: Must support open protocols such as Modbus TCP/CAN and provide a complete register mapping table.

- EMS Reporting Frequency: Supports minute-level data acquisition and at least 5 years of historical data storage.

- Remote Monitoring Platform: Features a cloud-based visualization interface and mobile app anomaly push notifications.

- Spare Parts Response Time: Clearly define local market inventory reserves for core modules and a 24/48-hour on-site service commitment.

- Warranty Coverage: Covers labor costs, travel expenses, and equipment replacement costs, leaving no ambiguities.

- Acceptance Test Items: Includes off-grid startup (black start), seamless grid/off-grid switching, and load fluctuation testing.

- O&M Training: Provide at least 3 on-site practical training sessions and certification for local technicians.

- Performance Guarantee Clause: Stipulate guaranteed system power generation or energy storage throughput for the first year and subsequent years.

Communication Phrases (Applicable to Tendering/Acceptance)

- “Please provide proof data for your company’s system’s Mean Time Between Failures (MTBF) in high-temperature and high-humidity environments in Africa.”

- “Please clearly explain how this EMS system handles communication protocol conversion between different brands of equipment?”

- “If a communication interruption occurs in island mode, what is the system’s emergency protection logic?”

- “Please list the detailed spare parts response time commitments for all critical spare parts involved in this project in the local area.”

Implementation Suggestions and Steps

- Early Technical Due Diligence: Conduct professional power consumption audits and simulations during the design phase.

- Strengthen Scoring Weight: Increase the weight of technical solutions and service capabilities to over 60%.

- Closed-Loop Acceptance: Strictly conduct full-scenario simulation testing according to design specifications.

- Establish Local Collaboration: Collaborate with partners like JNTech who possess localized service capabilities to establish long-term O&M relationships. —

Frequently Asked Questions (FAQ)

- Q1: Why do projects awarded at low prices often have high maintenance costs?

- A: Low-priced products typically cut corners on thermal management design, component redundancy, and after-sales service, leading to frequent malfunctions and a lack of support.

- Q2: What is the most critical acceptance criterion for a microgrid system?

- A: It’s the system availability rate (%). This represents the total percentage of time the system is able to function normally when needed.

- Q3: What if there is no local maintenance team?

- A: It is essential to require the supplier to deploy a remote monitoring platform for expert cloud-based diagnostics, along with a local spare parts inventory.

- Q4: What are the consequences of poor interoperability?

- A: It means that if a manufacturer goes out of business, your entire system may become unusable due to incompatible communication protocols, potentially leading to complete system failure.

Conclusion

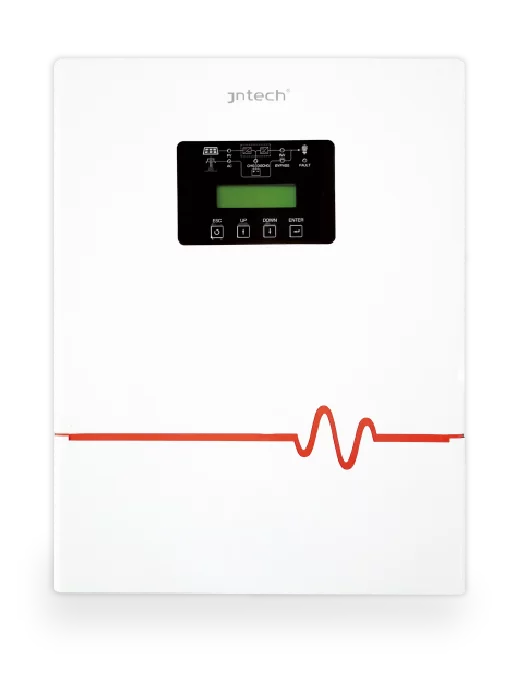

Microgrid construction is a long-term endeavor. As JNTech, we not only provide efficient hardware but also contribute to the stable operation of every microgrid through in-depth involvement in bidding recommendations, system integration, and localized technical services.

If you are optimizing bidding terms or need a maintenance assessment for your existing project, please contact us for professional tender document templates and technical consulting.

Web: www.jntechenergy.com 丨 WhatsApp: +86 18019566616 丨 Email: info@jnnewenergy.com