光伏微电网如何实现成本降低和效率提升:企业绿色转型综合指南

Release time: 2026-01-27

目录

In this article, we will deeply explore how photovoltaic microgrids can achieve cost reduction and efficiency improvement in industrial, commercial, and remote scenarios. Through optimized system configuration, intelligent energy management and scheduling, and full lifecycle management, we have compiled 10 core strategies and practical suggestions to help you significantly optimize the total cost of ownership (TCO) and shorten the payback period while increasing energy self-sufficiency.

Introduction: Why are Microgrids a “Game Changer” for Business Cost Reduction and Efficiency Improvement?

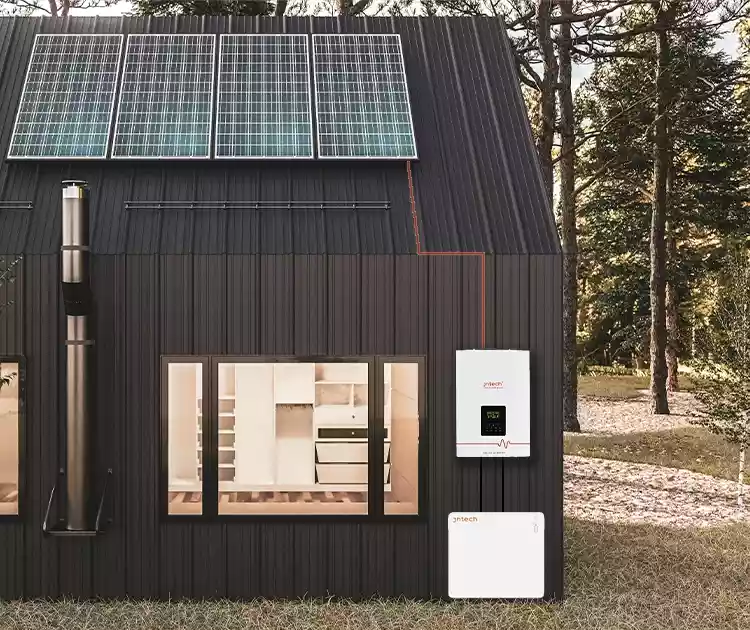

Under the dual pressures of increasing electricity price volatility and carbon neutrality targets, traditional power procurement models can no longer meet the needs of modern enterprises for cost control and energy flexibility. Photovoltaic microgrids, as a local power system integrating power generation, energy storage, and intelligent scheduling, not only enable enterprises to achieve electricity self-sufficiency but also transform energy from a “cost item” to a “revenue item” through energy storage peak shaving 和 microgrid scheduling.

What is a Photovoltaic Microgrid?

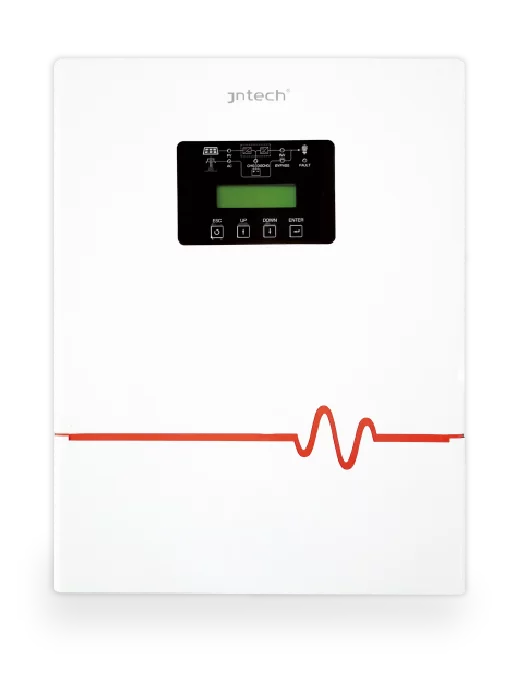

A photovoltaic microgrid is a miniature power generation and distribution system composed of distributed photovoltaic power generation, energy storage devices, energy conversion devices, loads, and monitoring and protection devices. It can operate in parallel with the external power grid or enter “island mode” to supply power independently when the external power grid is down, making it a core infrastructure for achieving efficient energy utilization.

Overall Path to Cost Reduction and Efficiency Improvement

Achieving the economic viability of photovoltaic microgrids hinges on the synergy of three dimensions: technological aspects (selection of high-efficiency equipment), management aspects (intelligent energy scheduling), and business aspects (policy incentives and financing optimization). Through this three-pronged approach, enterprises can reduce waste at the source and increase the value of every kilowatt-hour of electricity.

Core Section — “Ten Strategies for Cost Reduction and Efficiency Improvement”

1. Optimized System Configuration with Multi-Energy Complementarity

For different geographical conditions, adopt a multi-energy configuration such as “diesel-solar-storage” or “wind-solar-storage”. Through reasonable proportion design, reduce the proportion of expensive diesel power generation or compensate for the volatility of a single light source. – Practical Recommendations:

- Assess the match between annual solar resources and electricity load curves.

- 沟通脚本: “Please provide an optimal diesel/solar/storage configuration simulation plan based on our load curve, and explain its reliability under extreme weather conditions.”

2. Component and Layout Optimization on the Generation Side

Select high-efficiency, low-degradation photovoltaic components (such as N-type modules) and optimize the tilt angle based on the terrain.

- 清单:

- Confirm the component’s shading resistance performance.

- Check the wind resistance performance and installation accuracy of the support system.

- 沟通脚本: “Please provide the efficiency degradation curve and warranty details for this module model over the next 30 years.”

3. Energy Storage Scheduling and Energy Management System (EMS)

The EMS is the “brain” of the microgrid, responsible for real-time monitoring of power generation and consumption.

- Practical Recommendations:

- Deploy a smart EMS energy management system for millisecond-level response.

- Set priority levels: PV self-consumption > energy storage charging > surplus power grid connection.

4. Peak-Valley Arbitrage and Electricity Price Optimization

Utilize the energy storage peak shaving function to charge during off-peak hours and discharge during peak hours to supply the load, directly reducing electricity costs.

- 清单:

- Obtain the local time-of-use electricity price schedule and calculate whether the peak-valley price difference is sufficient to cover the energy storage cycle costs.

- Confirm whether the system has an automatic switching strategy.

5. Demand-Side Response and Load Management

Adjust production plans to match high-power loads with peak solar power generation periods.

- Practical Recommendations:

- Identify “flexible loads” within the park (such as water pumps, charging stations, and HVAC systems).

- Link with the EMS to activate relevant equipment when solar power output is sufficient.

6. Grid Connection Revenue and Surplus Power Sales Strategy

In areas that support surplus power grid connection, optimize grid connection revenue.

- Practical Recommendations:

- Understand the local power grid’s access restrictions and on-grid electricity price policies. – Install high-precision bidirectional electricity meters to ensure accurate billing data.

7. Integrated System Procurement and TCO Management

Avoid compatibility issues caused by fragmented procurement, focusing on the total cost of ownership (TCO) of the system rather than the initial purchase price of individual equipment.

- Practical Suggestions:

- Prioritize integrated suppliers with comprehensive capabilities.

- Communication Script: “Please provide a detailed breakdown of the system’s total cost of ownership (TCO) for 10 and 20 years, including the replacement plan for wear parts.”

8. Intelligent Operation and Maintenance and Remote Monitoring

Utilize a cloud platform for microgrid operation and maintenance, reducing downtime losses through preventive maintenance.

- Checklist:

- Does the system support real-time alerts on mobile devices?

- Can maintenance personnel perform remote firmware upgrades (OTA)?

9. Equipment Lifespan and Cycle Management

The lifespan of energy storage batteries directly impacts the return on investment.

- Practical Suggestions:

- Set a reasonable depth of discharge (DoD) to avoid overcharging and over-discharging.

- Monitor the temperature control system of the battery cluster to ensure it operates within the optimal temperature range.

10. Compliance and Subsidy Implementation

Utilize policy benefits to reduce initial investment pressure.

- Practical Suggestions:

- Consult local authorities regarding subsidies and tax incentives for distributed photovoltaic planning.

- Hire a professional consulting team to ensure the grid connection process is legal and compliant.

Brief ROI Tips

When evaluating the return on investment (ROI) of a microgrid, we recommend using the following approach: Static Payback Period = (Initial Investment – Subsidy Amount) / (Annual Electricity Savings + Annual Electricity Sales Revenue – Annual Operation and Maintenance Costs). When calculating, be sure to consider the 0.5%–1% efficiency degradation of the system over time. Due to significant differences in sunshine intensity and time-of-use electricity prices in different regions, the actual payback period usually ranges from 4 to 8 years (this is only an example/assumption, the specific calculation should prevail). —

Typical Application Scenario Examples

- Scenario A: Industrial Park (Grid-Connected)

- Cost Reduction Path: The core lies in peak-shaving and valley-filling 和 distributed photovoltaic planning. Using an EMS reduces transformer demand charges and avoids triggering high tiered electricity prices during peak load periods.

- Scenario B: Remote Community/Mining Area (Islanded)

- Cost Reduction Path: The core lies in “alternative fuel costs.” By using a high proportion of photovoltaics and energy storage, the operating time of diesel generator sets is reduced, significantly lowering fuel procurement and logistics costs.

Implementation Challenges and Countermeasures

- High initial investment: Consider Energy Management Contracts (EMC) or financing lease models to alleviate financial pressure.

- Complex technical integration: Choose a professional manufacturer with independent R&D capabilities for EMS and inverter communication protocols.

- Policy change risks: Reserve room for strategic adjustments in the solution design to ensure the system can flexibly adapt to future grid connection policy changes.

Supplier/Selection Communication Script

- “Please specify the switching time of your system when switching between grid-connected and off-grid states (does it support zero-blink switching)?”

- “Given our local climate conditions, what is the system’s protection logic under extreme high temperature/high humidity?”

- 请提供 microgrid project cases of similar scale from the past two years and share their actual power generation efficiency data.”

- “If energy storage needs to be expanded after 5 years, does your hardware architecture support mixed access of different capacity batteries?”

- “Please clarify the level of automation of the Demand Response function in this solution.”

- “For future operation and maintenance, what is the duration of your remote technical support and on-site response commitment?”

常见问题解答 (FAQ)

- Q1: Can a photovoltaic microgrid achieve 100% independent power supply?

- 一个: Technically feasible, but from an economic perspective, complete reliance on a microgrid requires a very high proportion of energy storage, resulting in high costs. It is usually recommended to maintain grid connection or equip a backup generator.

- Q2: Will the addition of an energy storage system extend the payback period? **

- 一个: Although initial CAPEX increases, in regions with significant peak-off-peak price differences, energy storage can significantly shorten the overall system’s payback period through peak-shaving and arbitrage.

- Q3: Does a microgrid affect existing power equipment?

- 一个: A properly designed microgrid includes anti-islanding protection and power flow control, which not only protects the load but also protects precision equipment through voltage stabilization.

- Q4: Is an Energy Management System (EMS) really necessary?

- 一个: Yes. A microgrid without an EMS is simply a collection of equipment; it cannot implement optimal strategies that dynamically adjust based on electricity prices and load, reducing efficiency gains by more than 30%.

结论

Achieving cost reduction and efficiency improvement in photovoltaic microgrids is a systematic engineering project. From initial planning and selection to later intelligent operation and maintenance, every detail determines the value of your energy investment. At JNTech, we understand the cost pressure behind every kilowatt-hour of electricity and are committed to providing you with the most professional and transparent microgrid solutions.

Want to know how much you can save on electricity costs for your project? Contact us for a free Total Cost of Ownership (TCO) estimate and initial solution assessment.