储能寿命、性能衰减和维护:如何最大限度地降低隐性成本?

Release time: 2026-01-28

Contents

The value of an energy storage system depends not only on the initial purchase cost but also on its economic performance throughout its entire lifecycle. So, how can we minimize the hidden costs associated with battery degradation through scientific operation and maintenance and predictive strategies, ensuring optimal Total Cost of Ownership (TCO) for our energy assets?

The Invisible “Hidden Costs”

In energy storage project operations, many decision-makers often focus only on the initial investment. However, battery capacity degradation, unexpected downtime, and premature equipment replacement constitute significant “hidden costs.” Without effective lifespan management, the actual return on investment may be far lower than expected. Understanding degradation mechanisms and establishing a professional maintenance system is crucial for asset appreciation.

Fundamentals of Energy Storage Lifespan and Degradation

Battery lifespan is typically divided into cycle life (number of charge-discharge cycles) and calendar life (natural storage time). Capacity degradation refers to the gradual decrease in the battery’s ability to hold energy over time. When the system’s available capacity drops to 70%-80% of its initial state, it is usually considered to have reached its end of life (EOL). Understanding the battery degradation curve is the first step in developing a maintenance plan.

Key Factors Affecting Lifespan

Temperature Management: Heat is the number one killer of battery life. Prolonged exposure to high temperatures accelerates chemical side reactions.

Check items: Are the air conditioning or liquid cooling systems functioning properly? Are the air ducts blocked?

Charge and Discharge Strategy (C-rate): Excessive current increases internal resistance loss and heat generation.

Check items: Is the system power output consistently at the edge of its peak limit?

SOC (State of Charge) Range: Prolonged operation at 100% full charge or 0% discharge damages the cell structure.

Check items: Is the BMS configured with reasonable charge and discharge depth protection?

BMS Algorithm: The quality of the balancing strategy directly determines the consistency of the battery cells.

Check items: Is the voltage difference between individual cells within a safe range?

Maintenance Strategies to Minimize Hidden Costs

Effective operation and maintenance can extend lifespan by more to 15%. We recommend implementing predictive maintenance combined with a remote monitoring platform for real-time data acquisition.

Example of Periodic Maintenance Checklist

| Period | Core Tasks | Example Monitoring Indicators (for reference only) |

|---|---|---|

| Daily Check | Monitor alarm logs, check operating environment temperature and humidity | System availability > 99% |

| Monthly Check | Filter cleaning, thermal imaging scan of cable connectors | Maximum single cell voltage difference < 50mV |

| Quarterly Check | In-depth battery balancing analysis, BMS firmware status verification | System SOH (State of Health) report |

| Annual Check | System full capacity test, safety circuit verification | Available power % assessment |

- Practical Recommendation: Utilize cloud-based life prediction models to intervene proactively before significant performance degradation occurs, avoiding business losses due to unexpected downtime.

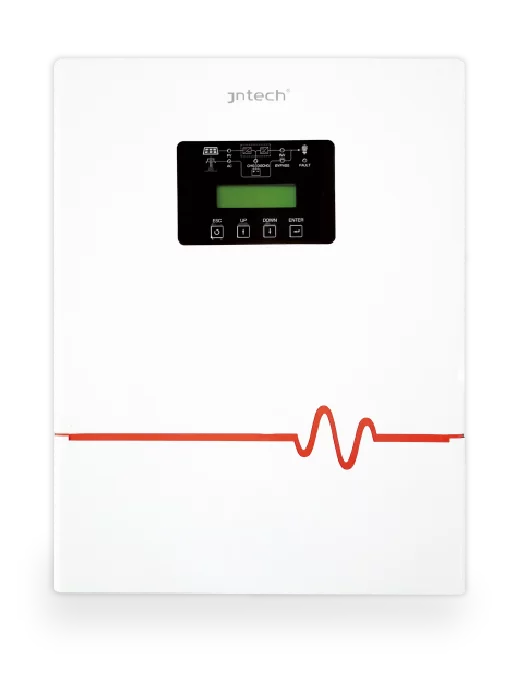

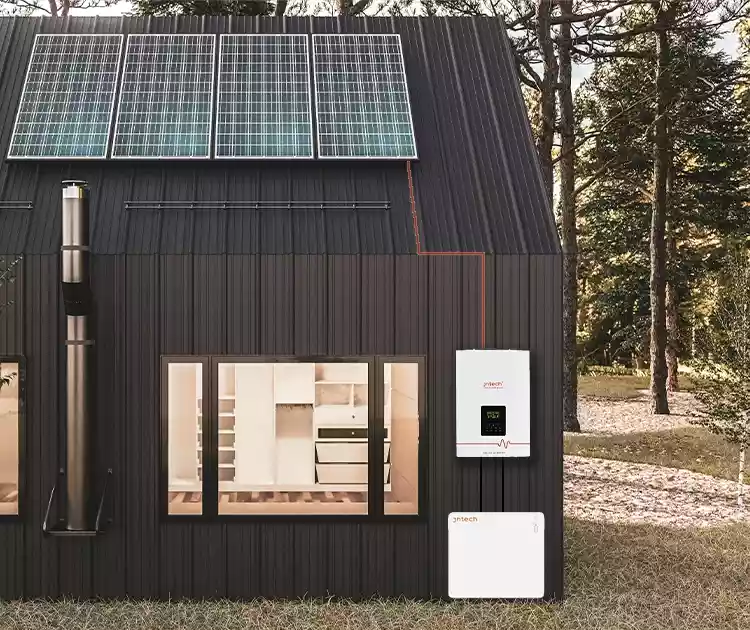

JNTech’s Technological Advantages and Service Support

As your energy partner, JNTech not only provides hardware but is also committed to reducing your hidden costs through full lifecycle services.

- Advanced BMS Algorithms: Our self-developed BMS supports life prediction models, generating real-time system SOH reports with industry-leading accuracy.

- Intelligent Thermal Management Strategy: Dynamically adjusts cooling intensity to ensure optimal cell temperature difference control, significantly slowing down calendar aging.

- Customized Maintenance Manuals: Provides targeted operating guidelines based on your specific application scenarios (such as peak shaving or backup power).

- Remote Monitoring and Technical Support: Provides on-site local installation monitoring and technical training services according to your needs.

- Rapid Response System: Local spare parts warehouses and technical expert teams ensure fault response times are significantly better than the industry average.

Brief TCO/ROI Tips

When evaluating energy storage projects, we recommend using the following calculation method: TCO = Initial Purchase Cost + Installation Cost + (Annual Maintenance Costs × Operating Years) + End-of-Life Replacement Cost – Salvage Value. For example, reducing manual inspection frequency by 50% through a remote monitoring platform and extending battery life by 2 years using thermal management strategies can reduce the levelized cost of electricity (LCOE) over the entire lifecycle by approximately 10%-15%.

Implementation Challenges and Mitigation Suggestions

Lack of Data Collection: Many older systems cannot obtain granular data. Suggestion: Deploy multi-point sensors and upgrade to IoT-enabled gateways.

Extreme Environmental Impact: Extremely high or low temperatures lead to thermal runaway risks. Suggestion: Strengthen passive thermal insulation design and increase active cooling power when necessary.

Insufficient On-site Operation and Maintenance Capabilities: Suggestion: Choose on-site operation and maintenance training provided by JNTech to improve the basic troubleshooting capabilities of the local team.

常见问题解答 (FAQ)

Q1: Does shallow charging and discharging really extend battery life?

一个: Yes. Avoiding deep discharge significantly reduces physical stress inside the battery cells, usually increasing the number of cycles.

Q2: Is the SOH displayed by the BMS accurate?

一个: It is an estimated value calculated based on parameters such as voltage, current, and temperature. JNTech uses a multi-dimensional fusion algorithm to provide higher-precision health status predictions.

Q3: Does the energy storage system need to be checked daily?

一个: If a comprehensive remote monitoring platform is available, daily checks can be done through system alerts. On-site manual in-depth inspections are usually recommended monthly or quarterly.

Q4: Why is the battery overheating even though the ambient temperature is normal?

一个: This may be due to an excessively high charge/discharge rate or internal balancing failure. It is recommended to immediately check the BMS logs and inspect the thermal management system’s filters.

结论

Successful operation of an energy storage system is a long-term endeavor. Through precise life cycle management and scientific operation and maintenance, you can not only protect your expensive battery assets but also minimize those invisible hidden costs.

If you wish to optimize the performance of your existing assets or are planning a new project, please contact us for a free initial life cycle assessment and professional operation and maintenance solution consultation.