JNTech Microgrid System White Paper: Energy Supply Solutions and Solution Design Standards in Complex Environments

Release time: 2025-10-22

جدول المحتويات

Expert Insights and the JNTech Innovation Manifesto – Leading the New Era of Multi-Energy Microgrids

Global Energy Challenges: Analysis of the Pain Points of Power Supply in Remote Areas

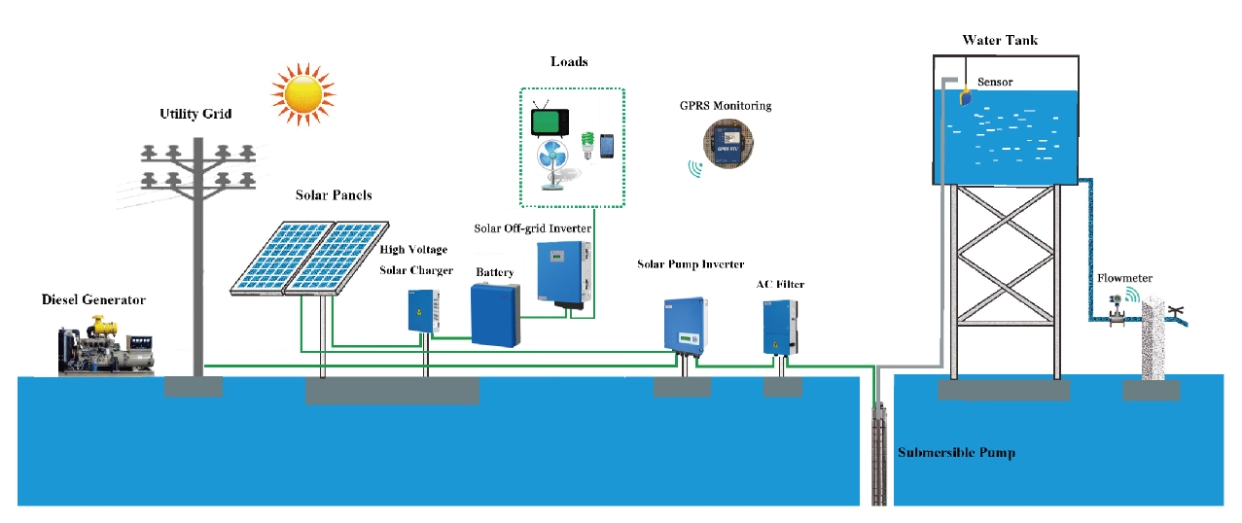

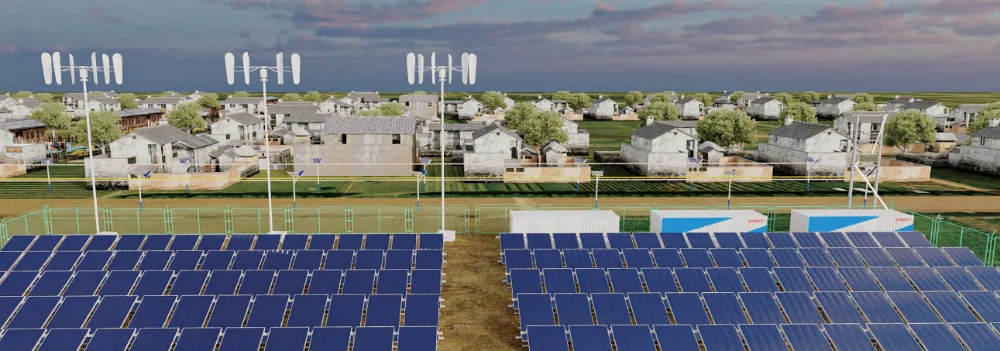

Faced with global power shortages and unstable utility grids, traditional energy solutions are unsustainable: diesel generators are costly and polluting; single photovoltaic systems are subject to weather constraints and lack reliability.

JNTech’s core strategy is to provide a one-stop multi-energy solution. By deeply integrating photovoltaic, wind power, energy storage, and diesel generators, and utilizing intelligent energy management systems (EMS) for coordinated dispatch, JNTech provides stable, sustainable, and environmentally friendly power to areas with unstable or insufficient utility grids.

Key Points for Microgrid Solution Selection and Compliance

Load Calculation and Demand Assessment

First, accurately define and calculate the load to avoid insufficient or wasted capacity.

Load Type: Resistive loads (lighting, heating, common in households/villages) and inductive loads (motors, pumps, common in commercial/projects). Inductive loads present starting inrush current issues, requiring special consideration for project-level systems.

Three core metrics must be accurate:

Peak power: determines the rated output of the PCS;

Average daily power consumption: determines the daily charging and discharging requirements for PV capacity and energy storage;

Maximum single unit load: impacts the stability of on-grid and off-grid control strategies, particularly addressing voltage drops and frequency fluctuations caused by motor startup.

Energy Storage Converter (PCS) Selection: The Core of the Microgrid

The PCS must maintain frequency and voltage stability and manage bidirectional energy flow. Performance requirements are even higher in off-grid scenarios. Selection Key Points:

Suitable for large inductive loads: Adopt industrial-grade designs with strong shock resistance (such as the high-power series);

Excellent off-grid performance: Supports three-phase imbalance, low voltage ride-through (LVRT), reactive power compensation, and SVG functions;

Intelligent collaborative control: Enables millisecond-level communication with EMS/BMS (RS485/CAN/TCP-IP, etc.), ensuring energy scheduling efficiency and battery safety.

Key Design Points

Worst Resource Month Design: Design based on the worst-performing month of the year (e.g., August, the rainy season, with a power output of 500 Wh/m²) is used as a benchmark to ensure that user loads can be met even in low sunlight, implementing a redundant design.

Energy Storage Depth and Endurance: Capacity is determined based on the customer’s backup power duration; LFP batteries are preferred, supporting deep discharge (e.g., 80% DOD) to ensure continuous power supply.

Thermal Management and Protection Rating: Outdoor cabinets must meet a minimum IP54/IP65 rating and be equipped with intelligent temperature control (e.g., industrial air conditioning) to accommodate operating environments ranging from -25°C to +55°C.

Safety and Fire Protection: Automatic cooling and active fire prevention measures are implemented to ensure system safety and rapid response in the event of high temperatures or faults.

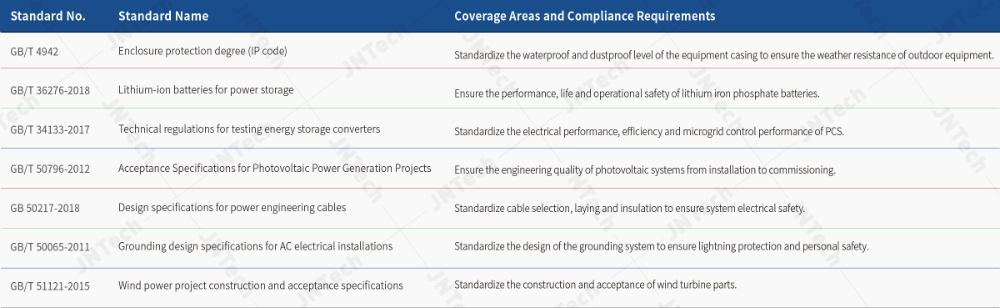

Design Specifications and Compliance

Microgrid design and implementation must be systematic and strictly adhere to relevant national and industry standards, covering photovoltaic, wind power, energy storage, electrical, and engineering acceptance, as a fundamental guarantee of quality, safety, and availability.

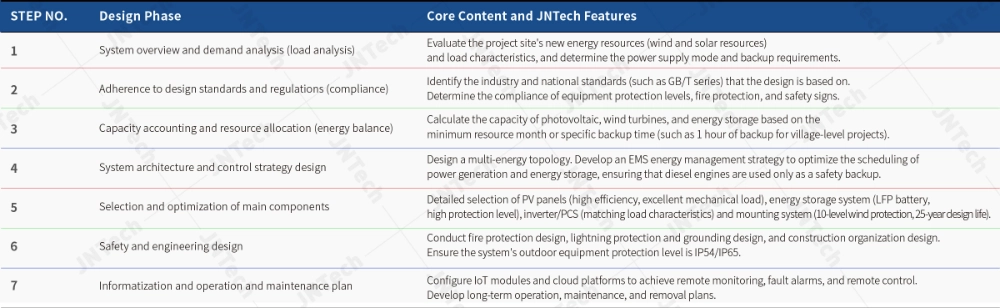

JNTech Microgrid Design Methodology and Process

JNTech provides customized microgrid solutions for various application scenarios, utilizing a scientific seven-step design process that covers the entire lifecycle from needs assessment to operations and maintenance, ensuring efficient and reliable systems.

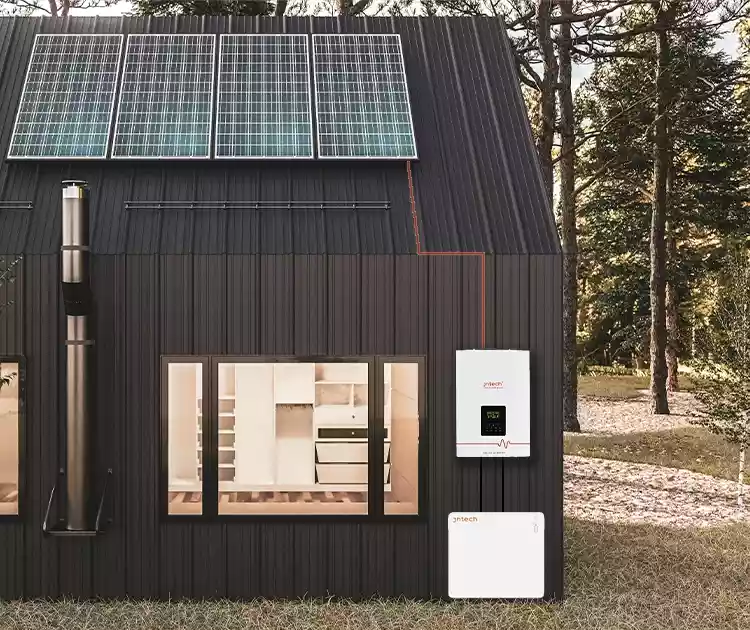

Integrated and Intelligent Design Concept: The solution is centered around “two highs”: high integration and intelligent operations and maintenance.

Integrated Cabinet Design: Integrates photovoltaic, wind power, EMS, fire protection, and communications modules to simplify deployment and reduce operations and maintenance costs.

Intelligent Remote Monitoring: LFP batteries and IoT modules enable cloud-based data upload and remote monitoring, solving the operational challenges of remote power plants.

Seven-Step Design Process

The design process is a closed-loop system that ensures the project is precisely aligned with customer needs and the local environment. It encompasses steps such as load assessment, capacity configuration, system linkage, control strategy, construction layout, commissioning, and post-operation and maintenance.

Core Component Selection Requirements (Taking a Village-Level Off-Grid System as an Example)

PV Modules: High power generation efficiency (≥6.15% improvement), weather-resistant, dust-resistant, and corrosion-resistant, having passed tests for wind, sand, salt spray, and ammonia, with a lifespan of up to 30 years.

Mounting System: Meets wind load resistance requirements of Level 10 (0.5 kN/m²), featuring galvanized corrosion protection and lightning protection to ensure long-term stability.

Integrated Cabinet: Integrates PCS, energy storage, and EMS, with an IP54 rating or higher, and operates in environments ranging from -25°C to +55°C. Each cabinet has a rated output of 100 kVA and built-in 112.6 kWh of LFP energy storage, enabling highly integrated and modular deployment.

قم بزيارة موقعنا الإلكتروني: www.jntechenergy.com

راسلنا على البريد الإلكتروني: info@jnnewenergy.com